REQUEST A BUDGET

Fapp manufactures different models of electrostatic powder coating machines in cables to reduce the adherence of its cover and/or reduce the penetration and migration of water in power cables, optical fibre, coaxial and other cables.

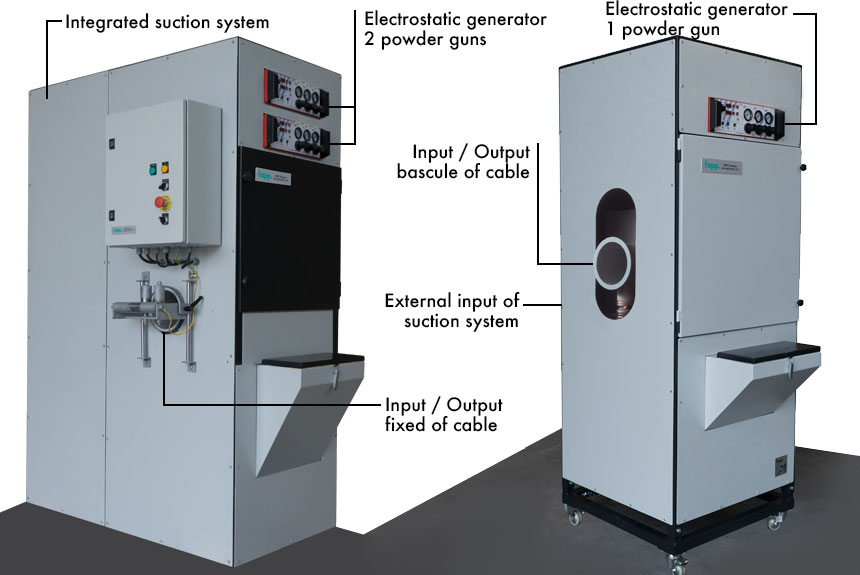

To facilitate the use of the different applications of each sector and cable, each model can be configured with different numbers of powder guns, as well as with optionals features such as flow control and bascule or fixed cable pass. The control modules allow to adjust all the important parameters of the process such as quantity, frequency of application and electrostatic charge. This ensures a constant uniform coating of the talc during the entire production process.

REQUEST A BUDGET

Powder coating machine models

| Suction System | Cable pass | Nº powder guns | Model |

| External | Fixed | 1 or 2 | TA-101 and TA-102 |

| External | Bascule | 1 or 2 | TA-201 and TA-202 |

| Integrated | Fixed | 1 or 2 | TA-501 and TA-502 |

| Integrated | Bascule | 1 or 2 | TA-601 and TA-602 |

Technical specifications

| Specifications | External Suction System | Integrated Suction System |

| Diameter max. Cable | 110mm | 110mm |

| Electrostatic charge | 100kV | 100kV |

| Nº powder guns | 1 or 2 | 1 or 2 |

| Nº jet pumps | 1 or 2 | 1 or 2 |

| Compressed air | 6 bar | 6 bar |

| Filling volume | 120L | 75L |

| Electric connection / generator power | 75w | 75w |

| Voltage | 230v | 230v |

| Cable pass | Fixed or bascule | Fixed or bascule |

| Models | TA-101, TA-102, TA-201, TA-202 | TA-501, TA-502, TA-601, TA-602 |

| Dimensions | width 700mm x depth 700mm x height 2000mm | width 740mm x depth 1016mm x height 2140mm |

| Weight | 220Kg | 335Kg |